Hand Soldering Electronics

Why Learn Hand Soldering?

Hand soldering skills required for many DIY (do-it-yourself) projects with electronics, for example…

- …building quad copters and other RC (remote control) airplanes, cars or boats

- …home-automation and IoT (internet of things)

- …custom PC builds including peripheral devices (like keyboards)

- …assembly of home-scale maker devices (for example 3D printers)

Hand soldering uses a solder iron and solder wire to connect component leads one-by-one.

Electronics projects often involve to…

- …solder components onto a PCB (printed circuit board)

- …solder connection wires to sensors or motors

- …desolder to repair/replace components, connectors or even small microcontrollers (MCUs)

How Does it work? …solder creates a permanent bond between metal work peaces…

- …solder melted to each part of a joint (usually between a component and a PCB)

- …after cooling the joint forms an electrical connection

- …soldering creates a metallurgical bond …it chemically reacts with the metal surfaces at the joints

- …solder typical melts above 180°C, however solder irons operate above 300°C to sustains enough heat

Solder Irons

For soldering electronics is is recommended to use a temperature regulated solder iron…

- …electronics control how fast it heats up …and how accurate operation temperature maintained during use

- …20 to 50 watts power rating (more is not necessarily better)

- …higher-wattage soldering irons can maintain a stable temperature longer

- …some pen style irons have a battery and/or USB-C support for portability

- …replaceable tip …different shapes (depending on the project)

- …conical tip …very fine …precision electronics soldering

- …chisel tip …soldering wires or other larger components

- …soldering iron stand (usually included with soldering stations)

- …prevents contact of the solder iron with flammable materials or accidental injury to your hand

- …brass sponge to keep the soldering iron tip clean

Some prominent options for solder irons typically recommended…

- …solder pens – Pinecil – Miniware TS

- …solder stations – Toolcraft ST-80D – Hakko FX-888D – Weller WE1010

How Do I Solder?

The process is rather simple, but requires practice…

- Turn the solder iron on (a temperature of 330℃ recommended for beginners)

- Hold the iron tip to the contact point for a few seconds

- Touch the solder wire to the contact point until it flows to the surface.

- Remove the solder iron when the contact area is completely covered

Not that applying to much heat can damage a component or a PCB surface contact plate.

Tinning The Tip

…improves the heat transfer from the solder iron to the components

Prepare your soldering iron by tinning the tip with solder:

- Clean the tip of the solder iron with the brass sponge

- Touch the solder to the tip of the iron and make sure the solder flows evenly around the tip

Desoldering

Remove components or make a correction to an electronic circuit…

Desolder a joint with solder wick (desoldering braid) [Entlötlitze]…

- Cut a small piece of braid and use a pincer to hold it (less heat-resistance)

- Place a piece of the desoldering braid on top of the joint

- Touch the tip to the top of the braid …wait until the braid absorbs the solder

Solder sucker [Entlötsaugpumpe] …handheld mechanical vacuum that sucks up hot solder with a press of a button

- Press the plunger down at the end of the solder sucker

- Heat the joint …place the tip of the solder sucker over the hot solder

- Release button to suck up the liquid solder

Solder Wire

EU regulation requires lead-free solders…

- …container mostly tin and copper (traces of other metals)

- …melting point about 30°C then normal solder …more activated (corrosive)

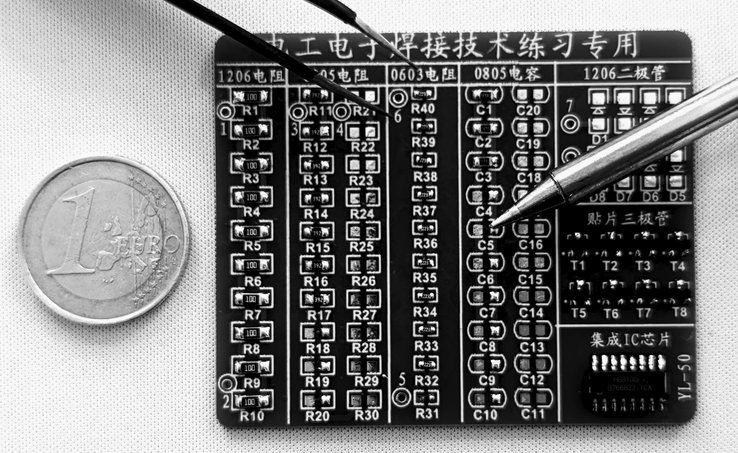

A 0.5mm diameter is recommend as solder wire for electronics components…

- …most suitable for electronics soldering …in particular SMD components

- …does include a very small amount of flux …recommend to use additional flux on the PCB

Recommended solder wire available in Germany… Lötzinn Felder ISO-Core “clear” 0.5mm (100g)

Why Use Flux?

Flux reduces metal oxides at the point of contact…

- …helps soldering and desoldering components…

- …improves electrical connection and mechanical strength

- …prevent toxic fumes from forming while soldering

- …chemically cleans metal surfaces

- …assist with the heat transfer …helps with flow-ability of the materials

- …protective barrier between the metal and the soldering heat

Types of flux…

- Rosin flux (r-type) used for electronics

- …can leave behind chloride ions and other corrosive residues

- …requires to remove leftovers of rosin flux agents from a PCB

- …to prevent long term corrosion related failures

- …typically done by means of 99% alcohol …or special PCB cleaner solution

- No-clean flux

- …leave less residue behind than the conventional R type flux

- …remains after soldering are non-corrosive and non-conductive

- …however residues left may be sticky and attract dust

- Water soluble flux …cleaned with deionized water and detergents

Multiple solutions to apply flux …flux found in paste form and semi-liquid gel

- …flux paste …use a paintbrush or cotton swab to apply

- …flux pen …very little excess and targeted application potential

- …flux paste with a syringe dispenser

Recommend flux pen available in Germany… Stannol Flussmittelstift FLUX X32-10i

Additional Tools

Depending on the amount of soldering work, the type of components used and the requirements on quality…

Accessible tools from the price point of view..

- Workmat usually from silicon with a heat resistance up to 500℃ …some include small compartments for components and screws

- Helping hands (or third hands) us adjustable clamps and a stable base to hold components and PCBs

- Precision Tweezers for small components (especially SMD)

Next Level

On the more expensive side …highly depending on the use-case:

- Hot Air Rework Station aka heat guns…

- …improves the capabilities to rework small SMT components on PCBs

- …this includs small packaged ICs (integrated circuits)

- Desoldering guns improve control during disassembly of components from PCBs…

- …combines a heating tip with a vacuum pump to remove solder from a joint

- …relatively expensive and usually not a useful investment for hobbyists

- Hot Plate for hot plate soldering of SMD components

- …solder paste used to place all SMD components on the PCB

- …hot plates heats the PCB from the bottom to melt the solder paste

- …this is a cheaper solution compared to a reflow oven

Small-scale Manufacturing

PCBA (printed circuit board assembly) at small to mid-scale manufacturing with PNP (pick and place) machines…

- …used to place surface-mount devices (SMDs) onto a printed circuit board (PCB)

- …remove manual labor …improve speed and placing of a broad range of electronic components

- Components…

- …components temporarily adhered to the PCB using a wet solder paste

- …solder paste dispensed on the PCB with an SMD stencils…

- …an SMD stencil is a laser cut stainless steel sheet masking the PCB only exposing parts requiring solder paste

- …vacuum-based parts picker (pneumatic suction cups)…

- …attached to a plotter-like device with a visual system for aligning…

- …to pick up and correctly place the components onto the PCB

- …component feeds aka feeders to supply components from tape reels

- …after component placement is finished the PCB is heated in a reflow oven

- …temperature follows a heating and cooling profiles according to solder material and component datasheet

- …components temporarily adhered to the PCB using a wet solder paste

Related open software and hardware – OpenPNP – Opulo (@stephen_hawes)