Data Center Liquid Cooling

Hardware

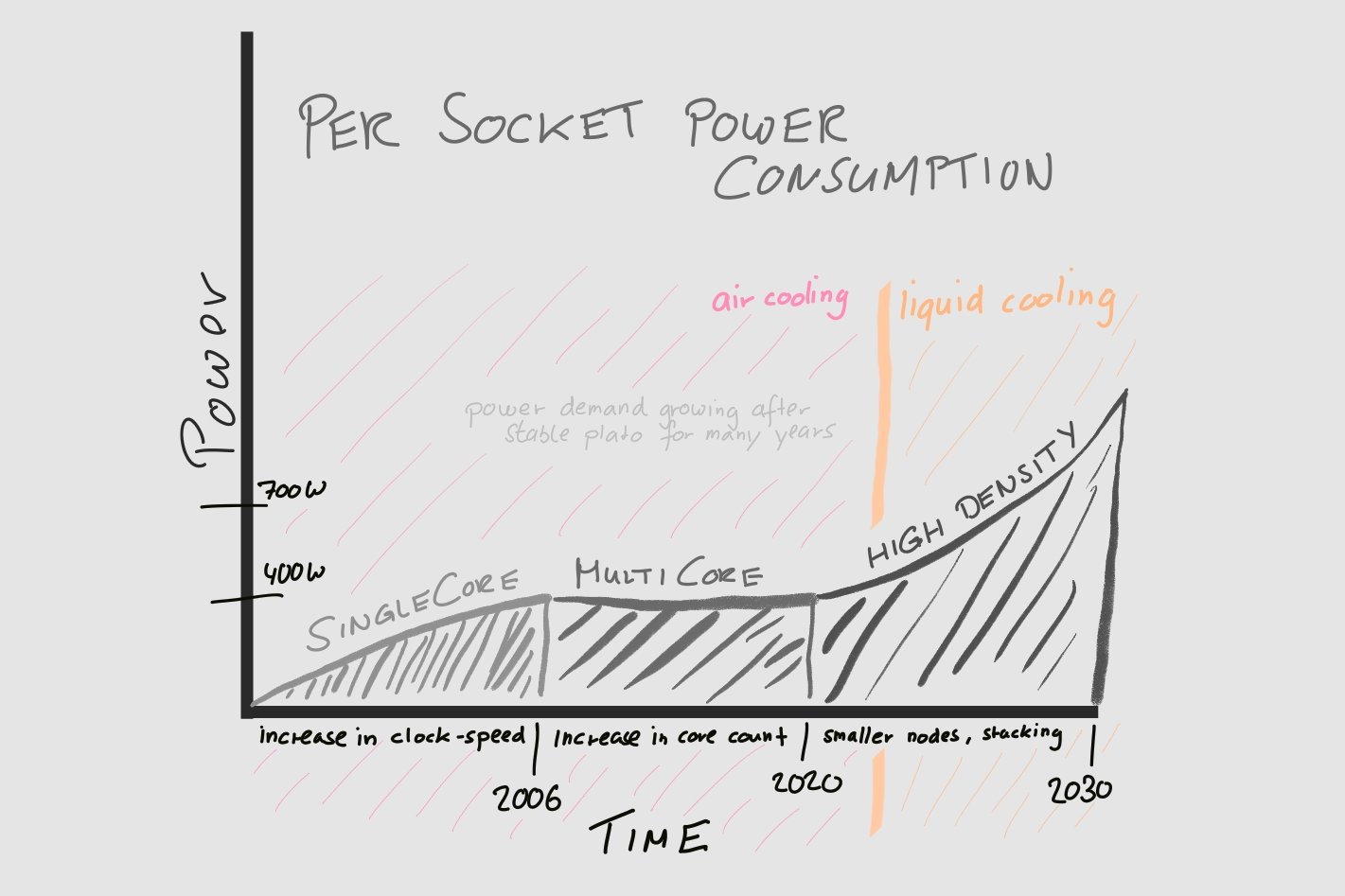

Thermal resistance needed to cool higher power devices is much lower than it was 10 or 20 years ago:

- …temperature difference between the processor case and the cooling medium

- …represent the effectiveness of a thermal solution …typically °C per watt

- …the lower the thermal resistance value, the more effective the cooling solution

- …relates to socket power and maximum case temperature limit of a device

Since ~2018 device power increases to enable further performance gains in processors:

- …increase in socket TDP (Thermal Design Power) across all vendors

- …clear trend to higher socket powers and lower temperature tolerances

- …increase in difficulty of cooling high TDP devices with air

- Note: High end memory (stacked memory) will require advanced cooling as well

Why Liquid Cooling?

Most air cooling solutions limited to around 400W TDP per socket, ~20kW per rack

- Challenges to cool higher TDP processors by increasing air-flow (as coolant)

- Fan power consumption energetically more expensive with increased air speed

Liquid cooling is required for TDPs higher then 700W per socket, >30kW per rack

- Enables to build higher density configurations to minimize rack-space

- Helps to optimize energy efficiency for growing cooling demands…

- …saves power up to 13% (typically ROI within one year)

- …therefore reduces operational costs (TCO) in data centers

- Lower noise levels …rely less on fans and airflow

Setup more complex …regular maintenance necessary

Direct-to-Chip vs Immersion

Two broad methods of cooling with liquid:

Direct-to-Chip (D2C/DTC) cooling, aka DLC (direct liquid cooling)

- 50-80% of heat capture …other components continue to be air-cooled

- …sometimes called conductive or Cold Plate liquid cooling

- Components are never in direct contact with the coolant

- Cold plates (heat sink) connected to a closed loop liquid circulation system

- Requires cold plates for each chip to absorb heat from the surface…

- …heat transfer coolant flowing through the channels in the cold plate

- …cold plate connected to a internal liquid cooling systems

- …components to create an effective cooling loop to remove heat

- Two types of DTC cooling…

- Single Phase …coolant does not change states (typically water)

- Two Phase …coolant changes states (from a gas to a liquid and vice-versa)

- Fluid boils out, is condensed and cycled back through system

- Slightly more expensive …more efficient (then single phase)

- Leakage …heat-transfer fluid does not corrode IT equipment

Immersion cooling (>50kw per rack)

- Over 95% heat cpatures within the cooling liquid

- Submerge components into a non-conductive liquid coolant…

- …dielectric fluid is in direct contact with IT components

- More involved/disruptive to install then DLC

- Three types of immersion cooling:

- Chassis Single Phase …immersion encapsulated within a sealed IT-chassis

- Tub Single Phase …shared immersion for all servers …vertical plane

- Tub Two-Phase …gas condenser on top of the tub to catch boiling fluid

In-Rack Liquid Cooling

Primary loop …facility water system (FWS)

- …provides cooling water to the racks

- …typically rear-door heat-exchangers (HX) for air-cooling

- …if available in-rack cooling connects to the primary loop

In-rack CDU (Cooling Distribution Unit)

- …separates facility and server cooling liquid at the rack

- …heat transfers between liquid, but never mixes

- …includes a pump to feed the CDM (Cooling Distribution Manifold)

- Questions:

- Pump maintenance …life-time …hot-swap …water filters

- Sensor …liquid leaking …component states …energy consumption

- Management interface …BMC & monitoring

System level liquid tubes …hoses kit

- Flexible tubing to connect the in-rack CDM

- Typically color coded red/blue aka hot/cold

- Typically dry break couplings for easy maintenance of servers